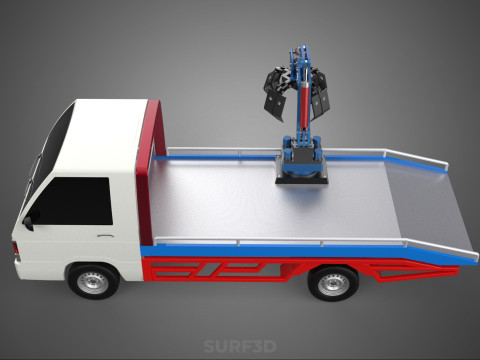

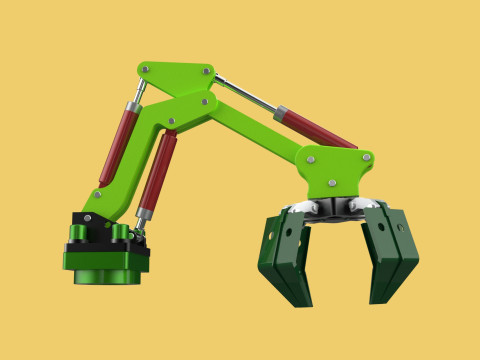

TRUCK PICK UP MOBILE CRANE HOIST LOAD LIFT GRABBER CLAW GRAPPLE 3D 模型

- 可用的格式: Rhinoceros: 3dm 21.22 MB3DS MAX all ver.: 3ds 3.52 MBBlender: blend 8.52 MBCollada: dae 9.38 MBAutoCAD (native): dwg 17.04 MBAutodesk FBX: fbx 10.95 MBGLB / GLTF: glb 4.57 MBIGES: iges 6.20 MB3DS MAX: max 22.24 MBWavefront OBJ: obj 6.62 MBACIS: sat 14.16 MBSketchUp: skp 5.92 MBSTEP: step 6.21 MBStereolithography: stl 7.00 MB

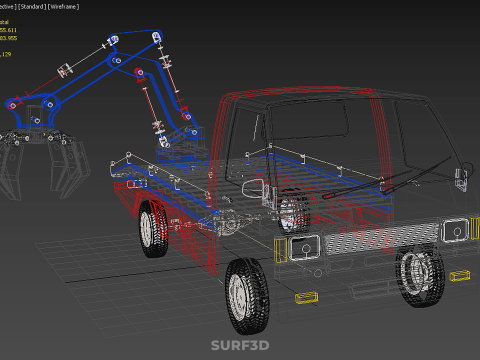

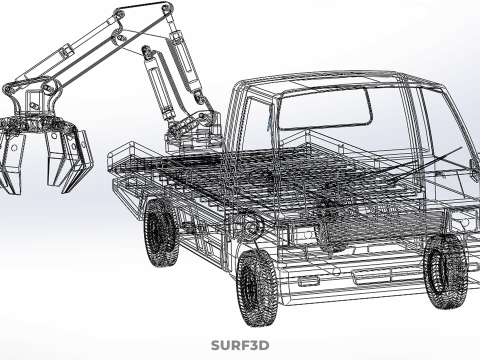

- 多边形:455611

- 顶点:383955

- 动画:No

- 纹理:No

- 操纵:No

- 材料:

- 低聚:No

- 集合:No

- UVW 贴图:No

- 使用插件:No

- 打印准备:No

- 3D扫描:No

- 成人内容:No

- PBR:No

- 人工智能培训:No

- 几何:Poly NURBS

- 包装 UVs:Unknown

- 日期:214

- 日期: 2025-06-13

- 项目 ID:579129

- 评分:

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

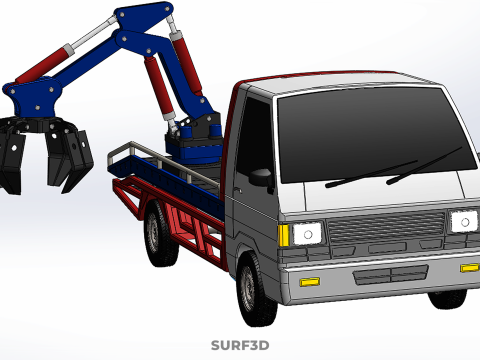

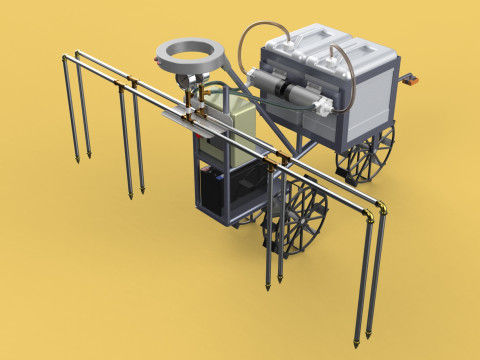

**Vehicle-Mounted Mobile Crane with Grapple Attachment (Pickup Truck Base)**

This entry describes a specialized configuration of material handling equipment consisting of a hydraulic crane mechanism mounted onto the chassis of a light commercial pickup truck. While the specific model "L300" refers to a particular series of light commercial vehicles produced by Mitsubishi Motors, the principle applies to adaptations using similar pickup truck platforms with adequate structural integrity and payload capacity. This system integrates the mobility of a road-legal vehicle with the lifting and manipulation capabilities of a crane, featuring a specialized 'grabber,' 'claw,' or 'grapple' as its primary end effector.

**Description:**

The core components of this system include:

1. **Base Vehicle:** Typically a sturdy pickup truck chassis. The vehicle serves as a mobile platform, providing transportation to various work sites and acting as the stable base from which the crane operates. Adaptations often involve reinforcing the chassis and suspension to support the weight of the crane unit and lifted loads. Outriggers or stabilizers are frequently incorporated to enhance stability during lifting operations, preventing tipping and ensuring safe load handling within the crane's working radius.

2. **Crane Mechanism:** A hydraulic boom crane is mounted directly onto the truck frame, often behind the cab or at the rear of the truck bed. This mechanism consists of a rotating base (slew system), a lifting arm or boom (which may be articulated, telescopic, or a combination), and hydraulic cylinders that power its movements (slewing, luffing, telescoping, and controlling the end effector). The crane is designed to lift loads vertically and move them horizontally within its operational range.

3. **Hoisting/Lifting System:** Integrated within the crane structure, this system is responsible for the vertical movement of the load. While some crane types use a winch and cable, systems designed specifically for grapple attachments often rely primarily on the articulation and extension of the hydraulic boom itself to achieve vertical positioning and lifting.

4. **End Effector (Grabber/Claw/Grapple):** This is the crucial attachment at the end of the crane boom that interacts directly with the load. Unlike hooks used for lifting objects with attachment points, a grabber, claw, or grapple consists of multiple articulated fingers or tines that can open and close hydraulically to grasp, enclose, and secure irregular or bulk materials. Common types include two-finger grapples, multi-tine grapples, and specialized configurations for specific materials like logs, scrap metal, or waste. A hydraulic rotator is often included between the boom and the grapple, allowing the operator to orient the attachment for optimal grasping and placement.

**Function and Application:**

This configuration is designed for tasks requiring both mobility and the ability to efficiently handle materials that are not easily lifted with standard hooks or slings. The pickup truck base allows the unit to access locations where larger, heavier trucks or dedicated mobile cranes might be impractical, including potentially uneven terrain or confined urban environments. The grapple attachment makes it particularly suitable for:

* Handling loose bulk materials such as scrap metal, waste, debris, or recycling materials.

* Logging and forestry operations for lifting and moving logs or branches.

* Certain construction tasks involving site clearance or material handling.

* Utility work involving poles or bulky equipment.

* Situations where objects lack specific lifting points and require external grasping.

The system's operation is typically controlled via a hydraulic control valve bank, often located adjacent to the crane base, or through a remote control system (wired or wireless) allowing the operator to position themselves for better visibility and safety.

**Variations:**

Key variations can include the specific type and capacity of the pickup truck chassis, the lifting capacity and reach of the crane boom, the design and size of the grapple attachment, the method of mounting the crane onto the truck, and the type of stabilization system employed. The term "L300" specifies a potential class of vehicle used, highlighting its use on a lighter, more maneuverable commercial platform compared to heavy-duty truck cranes.

KEYWORDS: Vehicle-mounted crane, Pickup truck crane, Mobile crane, Hydraulic crane, Material handling, Load lifting, Hoist, Grabber, Claw, Grapple, End effector, Attachment, Vehicle upfitting, Light commercial vehicle, Mitsubishi L300, Outriggers, Hydraulic system, Articulated boom, Telescopic boom, Lifting equipment, Waste handling, Scrap handling, Logging, Forestry, Construction site, Utility vehicle, Compact crane, Mobile lifting, Specialized vehicle, Cargo handling.

打印准备: 否如果你需要一个不同的格式,请打开一个新的支持票和为此请求。我们可以转换到 3D 模型: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 我们不转换 3d 场景 以及 .step、.iges、.stp、.sldprt 等格式。!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी